You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2011 RCZ THP200 midlife makeover

- Thread starter gwest

- Start date

You might just be looking at an "earlier design" solenoid and a "later design" solenoid here. But not sure in which order !!PSA solenoids (RHS of photo) screen only the central port, whereas the one from a BMW N13 engine has screens on all three ports

All of the timing gear, and a load of the turbo boost control bits, and more, had multiple revisions and changes on these engines as the years went on. If you look at an early timing chain for example, vs a current one, they're dramatically different as all the parts got improved to fix the myriad of issues. Many of the parts come in many many revisions, and a mixture is found on cars as random things got replaced over the years.

The way I understand it, you will receive the latest revision if you buy the part number from a Peugeot dealer, they have a system to supersede old parts with new parts, sometimes (but not always) you get bounced to a different part number (the Replaced By XXYYZZ). So if you were to go and buy a solenoid from them, it should be the latest design.

As an example, here's some pictures of three different tensioner revisions - https://www.peugeotrczforum.com/thr...-have-a-revised-timing-chain-tensioner.10674/

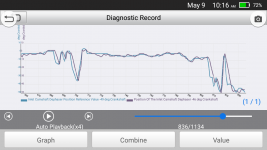

I subjected the inlet solenoid to the same ultrasonic treatment as the exhaust solenoid and it had the same remedial effect - no fault codes in the last three trips. Not even the P2263 turbo pressure code that has been an intermittent but continuous fault prior to this. So my efforts there were probably unnecessary. The plots below show the April 26 results when I had the fault codes and the later May 9 plot when there were none.It remains to be seen of course how long this good behaviour lasts and whether it will make any difference to the inlet solenoid. Which I am in the laborious process of trying to remove again.

Now I have to replace the cam sprocket bolts that I have retorqued three times to date.

Attachments

As part of fitting new sprocket bolts, after removing the two Vanos sprockets I decided that a session in the ultrasonic bath filled with kerosene could do them no harm. Afterwards I gave them a good blast out with compressed air so there would be little chance of dripping oil messing up the contact between the end of the camshaft and the sprocket boss. I don’t think cleaning the sprockets made any difference to their performance but happily there are still no camshaft timing fault codes.

I think there is still a misfire occasionally, but I will see if that develops further. In the meantime I can work on replacing the coolant level alarm that mistakenly thinks the expansion tank is empty. I don’t think it could be relied upon in an emergency- there is a RCZ on Carsales for $2k that is the result of an engine overheating.

There is also the matter of a noisy front RHS wheel bearing and a clunk from under the car that might be the lower engine mount? To replace that the driveshaft would have to come out so it would fit in with draining the transmission. I shouldn’t be bored for a while yet.

I think there is still a misfire occasionally, but I will see if that develops further. In the meantime I can work on replacing the coolant level alarm that mistakenly thinks the expansion tank is empty. I don’t think it could be relied upon in an emergency- there is a RCZ on Carsales for $2k that is the result of an engine overheating.

There is also the matter of a noisy front RHS wheel bearing and a clunk from under the car that might be the lower engine mount? To replace that the driveshaft would have to come out so it would fit in with draining the transmission. I shouldn’t be bored for a while yet.

Saw that one for 2k and wondered what happened. Guess timing chain issue, but overheating make sense.

While the car has been free of faults when driven sensibly if I give it full throttle and high revs it reacts very badly. Codes P1336 (misfire, cyl not specified) and P1339 (cyl 3 misfire) on two separate occasions. It feels and sounds like it is running on 3 cylinders. This led me to suspect the high pressure fuel pump. On the last occasion when I read the fault codes I was able to access the freeze frame data when the fault occurred.

Calculated Load Value : 81%

Revs : 6211rpm

Fuel Rail Pressure: 11910 kPa (119 bar)

I need to look elsewhere for the problem.

The first time I encountered P1339 I swapped the Peugeot coil on cylinder 3 with a spare I had from a BMW. It made no difference. My next move was going to be to swap the spark plug, but in the process of removing the coil leads I noticed that the openings on the wire connectors for cylinder 3 were larger than on the adjoining cyl 4. I tested this with a suitable probe and sure enough the fit on cyl 4 fitting was noticeably tighter than on cyl 3. Years ago on my MGF I had fixed a wildly uneven idle speed when I discovered the same thing on the connector to the ECU. Some of the connectors had been opened up, presumably by over-zealous probing with a multimeter.

This was one of those rare breakthrough moments in my shed and I forgot all about swapping the spark plug in my quest to work out how to tighten the connectors. The only way I could see to do this was to remove each wire from the plastic fitting. This turned out to be non-trivial. In fact something of a black art! But I eventually succeeded, and avoided stabbing myself with a sharp object. It was not clear how to tighten the fitting but by poking certain areas with a fine screwdriver I improved it. Next day I took the car out for a test drive, floored it, and broke down. Sigh! Same fault codes. I had read off one unfortunate who discovered, after replacing numerous components including the ECU, that the problem was broken wiring to the coil packs. I immersed myself in gloom wondering how I would diagnose that!

But, then I remembered Plan B, which was to swap spark plugs with no. 4. Now no. 3 spark plug looked ok, with just a slightly darker brown on the porcelain centre electrode. Took it out for a drive, it misfired on cue, but this time it was cyl. 4 (P1340)! I really don’t believe I have got off this lightly but have ordered a set of new plugs. And am trying to develop a more positive outlook on life.

Calculated Load Value : 81%

Revs : 6211rpm

Fuel Rail Pressure: 11910 kPa (119 bar)

I need to look elsewhere for the problem.

The first time I encountered P1339 I swapped the Peugeot coil on cylinder 3 with a spare I had from a BMW. It made no difference. My next move was going to be to swap the spark plug, but in the process of removing the coil leads I noticed that the openings on the wire connectors for cylinder 3 were larger than on the adjoining cyl 4. I tested this with a suitable probe and sure enough the fit on cyl 4 fitting was noticeably tighter than on cyl 3. Years ago on my MGF I had fixed a wildly uneven idle speed when I discovered the same thing on the connector to the ECU. Some of the connectors had been opened up, presumably by over-zealous probing with a multimeter.

This was one of those rare breakthrough moments in my shed and I forgot all about swapping the spark plug in my quest to work out how to tighten the connectors. The only way I could see to do this was to remove each wire from the plastic fitting. This turned out to be non-trivial. In fact something of a black art! But I eventually succeeded, and avoided stabbing myself with a sharp object. It was not clear how to tighten the fitting but by poking certain areas with a fine screwdriver I improved it. Next day I took the car out for a test drive, floored it, and broke down. Sigh! Same fault codes. I had read off one unfortunate who discovered, after replacing numerous components including the ECU, that the problem was broken wiring to the coil packs. I immersed myself in gloom wondering how I would diagnose that!

But, then I remembered Plan B, which was to swap spark plugs with no. 4. Now no. 3 spark plug looked ok, with just a slightly darker brown on the porcelain centre electrode. Took it out for a drive, it misfired on cue, but this time it was cyl. 4 (P1340)! I really don’t believe I have got off this lightly but have ordered a set of new plugs. And am trying to develop a more positive outlook on life.